It may include technical consultation services protocol development management of the irradiation and microbiological testing plus final reporting.

E beam sterilization validation.

A the sterilization dose needed to support a claim of sterility sal and b the maximum acceptable dose identified in high dose testing as noted above.

E beam sterilization is very gentle on product material and packaging when compared to gamma sterilization and is compatible with most materials.

During his previous employment he learned the ins and outs of medical device sterilization via e beam x ray irradiation.

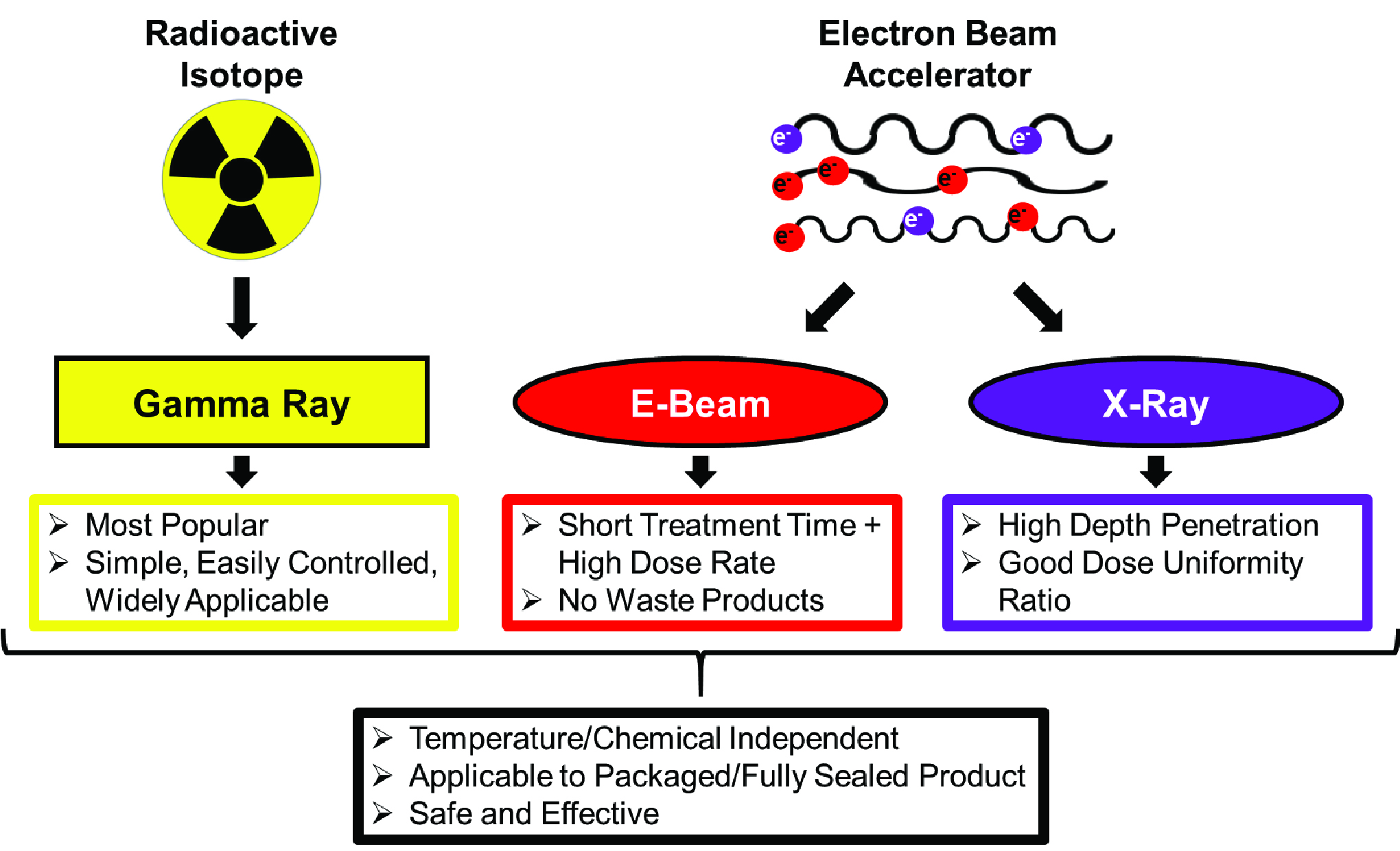

Electron beam e beam irradiation is a form of ionizing energy that is characterized by its low penetration and high dosage rates.

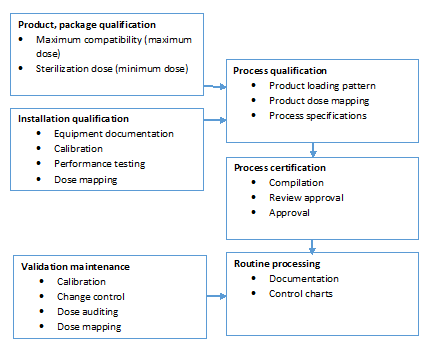

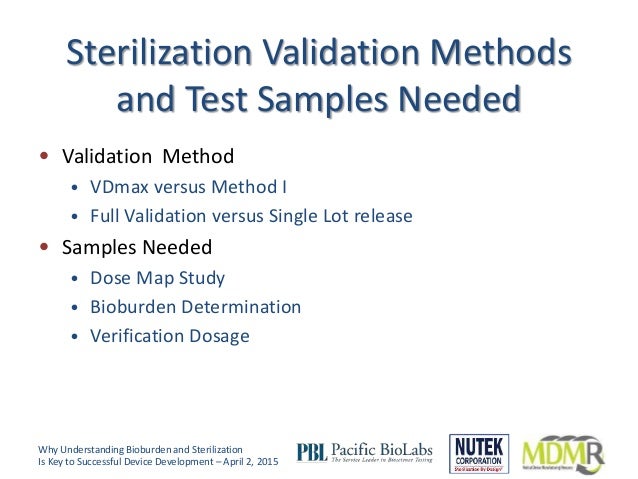

The first two steps of the process dose range validation for e beam consist of determining.

Steri tek provides turnkey sterilization validation packages per iso 11137 vdmax for companies that wish to outsource their sterilization validation work.

Check back in for my future blog how do i validate my medical device for e beam sterilization for details on what each step entails.

This validation process is comparable to that of gamma sterilization and it is simpler than the process for eto sterilization.

Materials testing and establishing maximum dose.

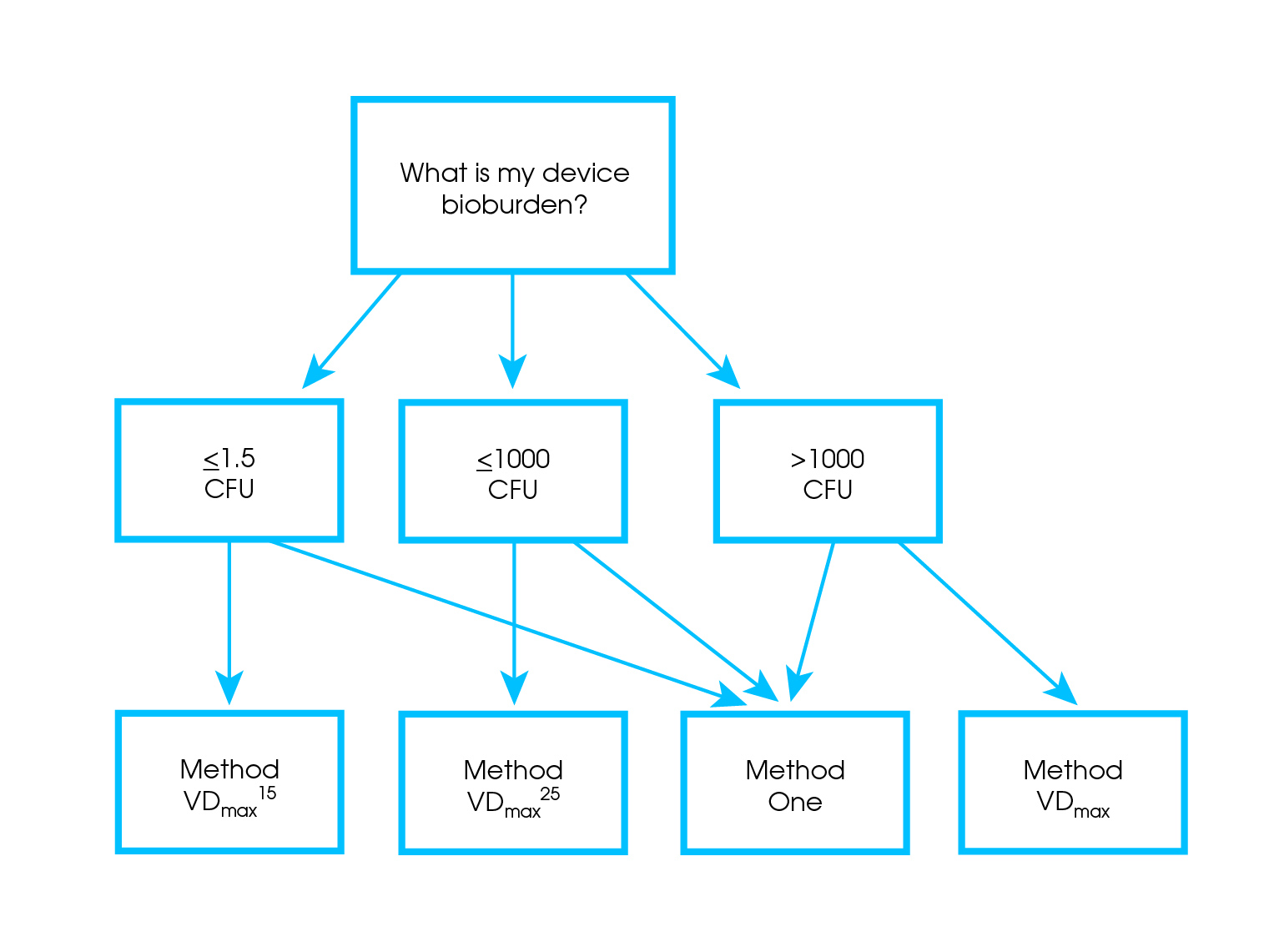

Overview of an e beam irradiation validation for healthcare products prior to beginning routine processing with electron beam e beam irradiation a product with a sterile claim needs to complete a validation process to ensure the sterility assurance level claimed is achieved.

Confirm that the sterilization process was validated by reviewing the validation study.

The sterilization validation process.

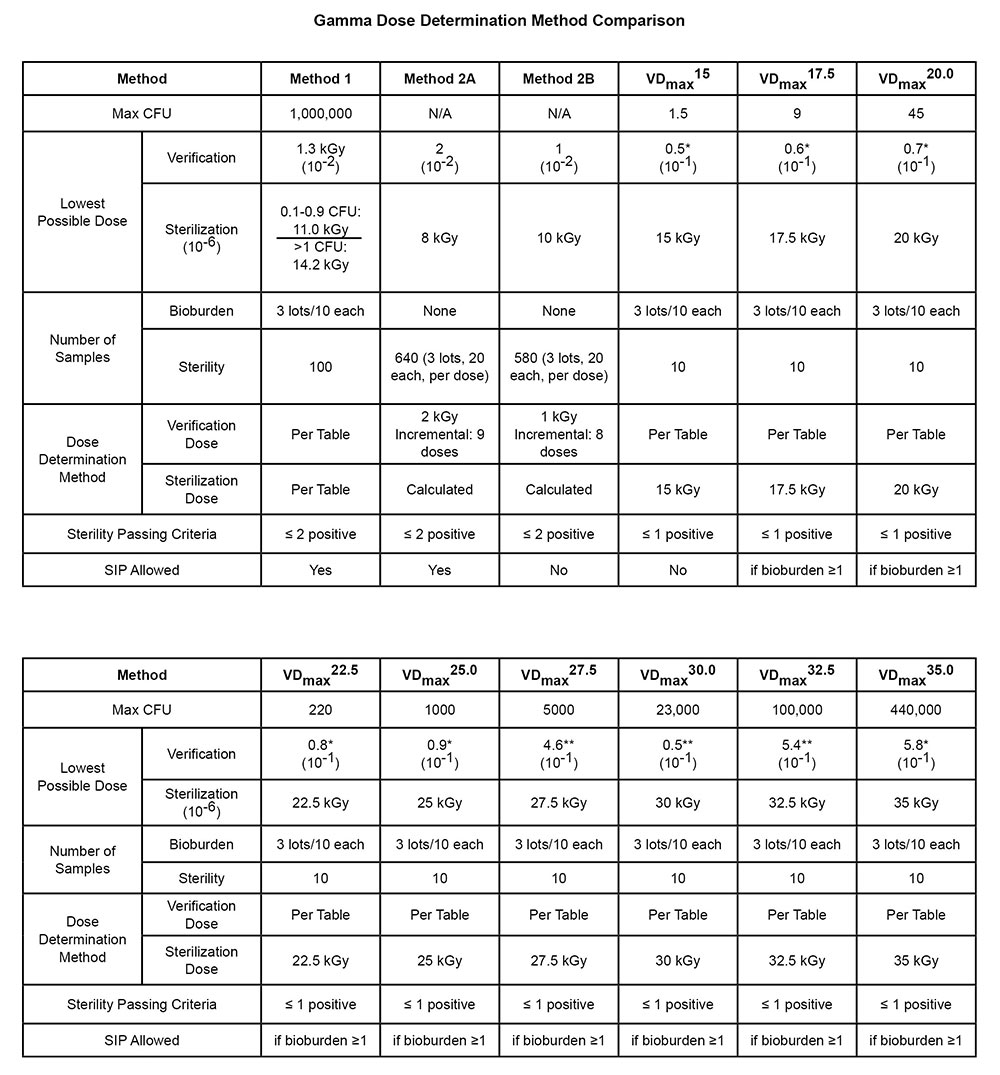

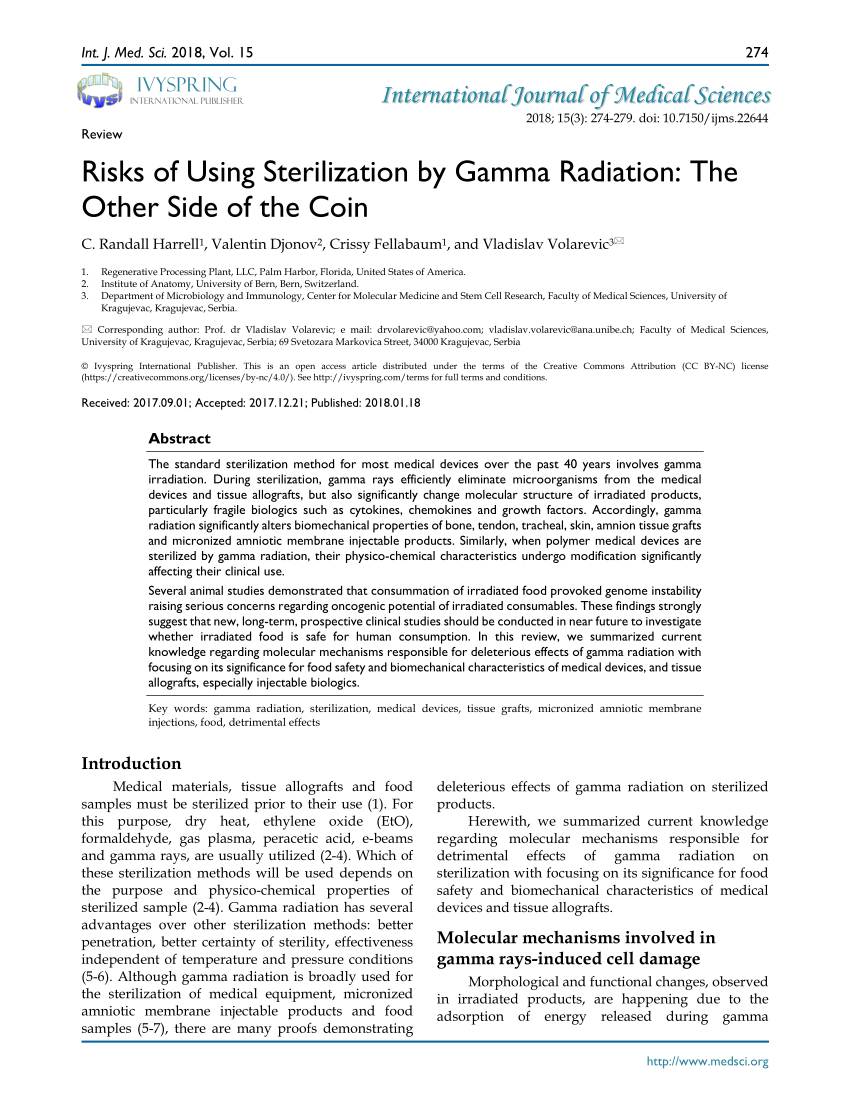

The sterilization validation requirements are set forth in the international standard iso 11137.

The beam a concentrated highly charged stream of electrons is generated by accelerators capable of producing continuous or pulsed beams.

To claim your product is sterile after e beam treatment you must perform several validation steps as regulated by iso 11137.

He now brings this knowledge to steri tek in order to help guide customers through the validation of terminal sterilization for medical devices.